USE THE BEST LINE SHAFT BUSHINGS (GUIDE BEARINGS) FOR PUMP & ROTATING ELEMENT APPLICATIONS SIMSITE®

iCrowdNewswire

Aug 24, 2021

USE THE BEST LINE SHAFT BUSHINGS (GUIDE BEARINGS) FOR PUMP AND ROTATING ELEMENT APPLICATIONS – SIMSITE®

SIMSITE® Structural Composite Line Shaft Bushings (Guide Bearings) can extend the life of your equipment and save the equipment from significant damage. SIMSITE® Composite Guide Bearings and Line Shaft Bushings outlast and outperform bronze, rubber, thermoplastic, engineered thermoplastic, rubber, telfon, and elastomer bearings!

They are uniquely different from any other line shaft bushings because they are a structural composite – they will not break down, deform, or cold flow like other bearings. The fibers in SIMSITE® line shaft guide bearings are continuously interwoven in a multidimensional weave.

SIMSITE® Bearings and Bushings are precision machined and will not break down, cold flow, or melt like thermoplastic, engineered thermoplastic, or rubber guide bearings. They are significantly superior to other guide bearings and bushings, offering rigidity to the rotating element as well as self-lubricating qualities without galling, or seizing, on the shaft.

SIMSITE® Bearings and Bushings are 100% precision machined from solid blocks of the patented SIMSITE® Structural Composite, which insures maximum strength and longevity because the load of the shaft is distributed equally over the length of the bearing. SIMSITE® Bearings are also much better than traditional bearings when operating in corrosive environments such as Sewage, Waste Water, Seawater and River Water Applications.

SIMSITE® Guide Bearings and Line Shaft Bushings hold the pump shaft more securely, which reduces shaft deflection & vibration and improves longevity. Because SIMSITE® Bearings are inert, electrolysis is greatly reduced when the bearings are used.

SIMSITE® Guide Bearings will not corrode in seawater, or wastewater, and they seal against the casing, or the bearing housing, preventing leakage behind the bearing, and eliminating the damage of corrosion and erosion. This is critical because it insures that the shaft will be secured properly reducing the risk of damage to the entire rotating element.

USE THE BEST LINE SHAFT BUSHINGS (GUIDE BEARINGS) FOR PUMP AND ROTATING ELEMENT APPLICA TIONS – SIMSITE®

SIMSITE® Guide Bearings and Line Shaft Bushings hold the pump shaft more securely, which reduces shaft deflection & vibration and improves longevity. Because SIMSITE® Bearings are inert, electrolysis is greatly reduced when the bearings are used. SIMSITE® Guide Bearings will not corrode in seawater, or wastewater, and they seal against the casing, or the bearing housing, preventing leakage behind the bearing, and eliminating the damage of corrosion and erosion. This is critical because it insures that the shaft will be secured properly reducing the risk of damage to the entire rotating element.

SIMSITE® Composite Guide Bearings and Line Shaft Bushings offer safety as well as longevity and have a proven track record with thousands of installations in service over the past 101 years!

SIMSITE® LINE SHAFT BUSHINGS – EXTEND ROTATING EQUIPMENT LIFE!

- Ask any engineer to describe the ideal material for Line Shaft Bushings (Guide Bearings) What would they say?

- The Bearings should be Self-Lubricating to prevent seizing and galling.

- The Bearings should have rigidity to reduce radial movement and shaft deflection, vibration, and noise.

- The Bearings should be a Structural Composite which does not Deform, or Cold Flow under Pressure or Temperature.

- The Bearings should be able to take Dry–Starts.

- The Bearings should have a Low CoeNcient of Friction and a highly polished surface to resist wear of the shaft.

- The Bearings should have excellent Mechanical Strength and a High PV (Pressure x Velocity) rating to withstand high radial loading and torque.

- The Bearings should be Corrosion & Erosion Resistant and should not support electrolysis.

- The Bearings Should be able to be lubricated by water, sea water, river water, oil, grease, or the fluid being pumped.

SIMSITE® GUIDE BEARINGS (LINE SHAFT BUSHINGS) WILL NOT TEAR APART FROM BARNACLES, SAND, OR SILT

Unlike rubber, extruded, non-structural composites, thermoplastic, or engineered thermoplastic bearings; Simsite® Line Shaft Bushings (Guide Bearings) are made from structural graphite fibers which are continuously interwoven in a tri- dimensional weave, and therefore are much stronger and much more durable than rubber, elastomer, non-structural composite, or plastic. They are not subject to cracking, breaking, melting or deforming under pressure and temperature like thermoplastic and elastomer bearings.

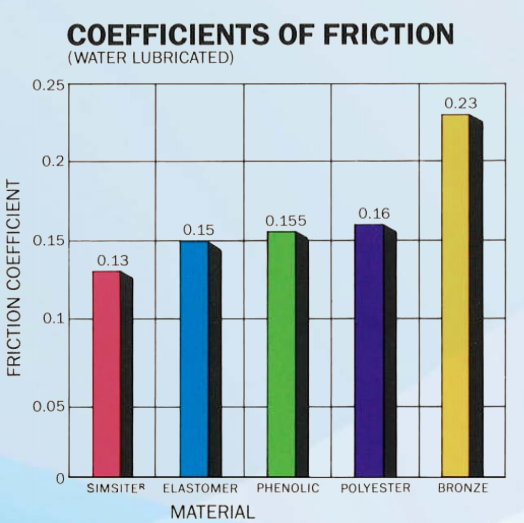

SIMSITE® GUIDE BEARINGS (LINE SHAFT BUSHINGS) HAVE A LOW COEFFICIENT OF FRICTION

Simsite® bearings have an extremely low coemcient of friction, because they have loose graphite and other lubricants embedded throughout the structural engineered composite, which gives the bearings self-lubricating characteristics. When lubricated by water, oil, or grease, Simsite® bearings to hold up much better against sand, silt, or barnacle erosion.

SIMSITE® GUIDE BEARINGS (LINE SHAFT BUSHINGS) WILL NOT FAIL, OR SEIZE, ON A SHAFT

the event that lubrication is suddenly cut off from the bearings, Simsite® bearings will not melt, deform, cold flow, or seize on the shaft like rubber, babbitt, bronze, plastic, engineered thermoplastic, or elastomer bearings. Simsite® bearings have loose graphite embedded in the resin system and can withstand dry running for a period of time before the clearances will start to open up, but the bearings will never completely fail. This has saved the life of many rotating elements.

CORROSION, EROSION, & ELECTROLYSIS PROBLEMS ARE ELIMINATED WITH SIMSITE® GUIDE BEARINGS!

SIMSITE® Guide Bearings (Line Shaft Bushings) seal against the casing or bearing housings which prevents leakage and eliminates corrosion and erosion damage. This is critical because it eliminates the risk of severe damage to the entire rotating element.

SIMSITE® Guide Bearings (Line Shaft Bushings) can be manufactured split, or unsplit, for ease of installation. Split Line Shaft Bushings enable the bushings to bechanged without taking the entire rotating element apart.

LONGER LIFE FOR THE COMPLETE ROTATING ELEMENT WITH SIMSITE® GUIDE BEARINGS (LINE SHAFT BUSHINGS) WITH SIMSITE® IMPELLERS:

Because Simsite® Bearings hold the shaft more securely than conventional bearings, radial movement in the shaft is reduced. This increases the life span of the entire rotating element.

When you combine a Simsite® Impeller and casing rings with a Simsite® Guide Bearing the length- to-diameter (L/D) of the rotating element is reduced. The stability of the rotating element is therefore improved because of the lower mass.This lower mass (85% Less Weight than bronze, or stainless steel) reduces shaft deflection and vibration!

SIMSITE® STABILIZING BUSHING FOR ALL PUMPS & ROTATING EQUIPMENT!

PATENT NO 10,731,645!

- Reduces Shaft Deflection

- Reduces Pressure in the Seal Chamber

- Protects Mechanical Seals

- Eliminates Seal Erosion

- Extends Bearing Life

- Extends Seal Life

- Extends Motor Life

- Split for Easy Installation

- Structural Composite

- Reduces Vibration

- Prevents Contaminants

Any Shaft, or Rotating Element, or Mechanical Seal can now be secured with the SIMSITE® Structural Composite Split Stabilizing Bushing! The SIMSITE® Split Stabilizing Bushing Reduces Shaft Deflection & Vibration and is 100% machined on the outside as well as the inside from solid blocks of the patented SIMSITE® Structural Graphite Composite. The SIMSITE® Split Stabilizing Bushing is NOT cast, or molded. The two halves of the stabilizing bushing are 100% concentric with each other and can easily be manufactured to specific bore and shaft sizes.

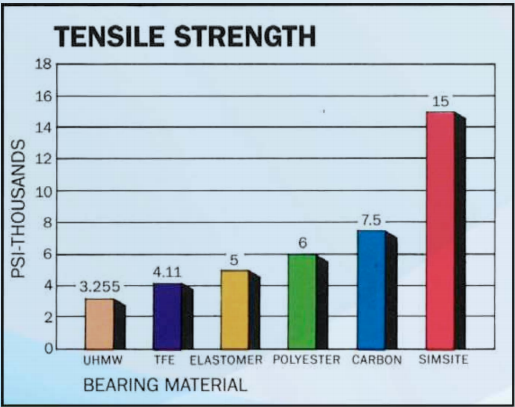

SIMSITE® GUIDE BEARINGS (LINE SHAFT BUSHINGS) HAVE HIGH MECHANICAL STRENGTH

SIMSITE® bearings are not cast, poured, extruded, or molded, rather, they are a structural composite. They are precision machined from a solid bar of our patented Simsite® material. Because the fibers are not chopped up, or cut, Simsite® bearings have a much higher shear strength, bond strength, flexural strength, and tensile strength. Simsite® bearings will not crack or break like carbon, or non-structural composite bearings. The high mechanical properties enable the bearings to withstand higher loads and torque requirements.

SIMSITE® GUIDE BEARINGS (LINE SHAFT BUSHINGS) WILL NOT DEFORM (COLD FLOW) OR BREAK DOWN UNDER PRESSURE

SIMSITE® Bearings are a structural composite. (The fibers are not chopped, cut, or macerated. They are continuously interwoven in a multidirectional weave) SIMSITE® Bearings will not break down under pressure like thermoplastics bearings, or deform (cold flow) under pressure or temperature like engineered thermoplastic bearings like PEEK, and fluoropolymers like Teflon. SIMS PUMP

Contact Information:

SIMS PUMP Valve Company, Inc. 1314 Park Avenue

Hoboken, New Jersey 07030 USA

Omce: 1-201-792-0600

Mobile: 1-201-323-6087

Email: Simsite@Simsite.com

Email: SimsPump@Simsite.com

www.SIMSITE.com

www.ImpellerStore.com